TECH BUILDS BIG REP AND MAKES BIG MONEY LEARNING HOW TO REMOVE BROKEN EXHAUST MANIFOLD BOLTS QUICKLY & EASILY

S-N-A-P… the unthinkable happened, an 8-millimeter tap busted off in the cylinder head exhaust manifold mounting port of a 2015 Ford F-550 6.8L Triton. Worse yet, it happened during a botched repair attempt a franchise shop made on a delivery truck for a major metropolitan newspaper. Every day the vehicle is offline means lost revenue and productivity.

This is when Dave McCauley, an independent shop owner in Pittsburgh, Pennsylvania took the job over from the franchise facility. “Due to the broken tap, it looked especially grim that morning,” McCauley said. “The franchise guy’s assessment was that the engine would have to come out, the head had to come off and it would have to go to the machine shop.”

However, thanks to his ProMAXX Tool Exhaust Manifold Bolt Repair (EMR) kit and extra tooling, the 15-hour-plus task to remove and reinstall the cylinder head, and another 10 hours to remove and reinstall the engine, was shortened to one half-hour. And, there was no need to replace the expensive head. This made the customer very happy.

BUILDING HIS MECHANIC BUSINESS FROM SCRATCHAfter working at dealerships and shops for years as a mechanic, in 2011 McCauley built his own business from the ground up. “I wanted the freedom to do it my way,” he said. “It wasn’t easy. I had to acquire tools, recruit qualified employees and most importantly, attract paying customers.”

MAKING A NAME BUSTING BROKEN BOLTS

Now, the owner/operator has earned a name for himself, especially when it comes to repairs that involve removing broken bolts. He uses several different ProMAXX Tool kits that allow him to work on Ford, GM, Dodge engines and more.

“Thanks to ProMAXX Tool’s kits, I’ve done thousands of broken bolt repairs,” McCauley said. “And, I’ve never had to pull a motor to do one yet. Over the years, I’ve made hundreds of thousands of dollars fixing exhaust manifolds. Before I got my ProMAXX kit, I wouldn’t touch an EMR job.”

WEATHER EXTREMES MAKE BOLTS BREAK

McCauley explained that Northeastern weather extremes and engine cycling mean exhaust manifold bolts only go so far before they break. Whether vehicles are pulling trailers, pushing snow plows, or simply driving kids to school, their owners need to get them back on the road fast.

The mechanic at the franchise shop did not use the right tools on the broken manifold bolts. When he told the customer the broken tap would push the bill up to $10,000, the newspaper refused to pay. Hearing about McCauley’s reputation with broken bolts, the paper took the truck to him.

McCauley’s initial step to remedy the situation was to mount the ProMAXX Tool Rocky II guide plate. The jig facilitates the removal of broken exhaust manifold bolts on Ford 4.6L, 5.4L, 6.8L gas engines, and the 6.0/6.4L Power Stroke Diesel.

Next, he prepared to remove the broken tap. Taps do not break off nice and flat, they are left jagged. They will eat up any tooling when drilling is attempted. ProMAXX Tool’s Platinum ProMill bits grind through burrs, remove corrosion, and flatten the ends of obstructions – including taps.

McCauley’s initial step to remedy the situation was to mount the ProMAXX Tool Rocky II guide plate. The jig facilitates the removal of broken exhaust manifold bolts on Ford 4.6L, 5.4L, 6.8L gas engines, and the 6.0/6.4L Power Stroke Diesel.

NOT IMPOSSIBLE TO DRILL OUT A TAP

“There’s a myth that it’s impossible to drill through a tap,” said ProMAXX Tool President Jeff Del Rossa. “Our ProDrill Platinum machine-shop-grade bits rip right through them. They are excellent for drilling extremely hard materials including broken extractors and taps.”

After using the Platinum Drill Bits, McCauley went to work with a reamer bit. Hot orange sparks shot from the bolt hole as he drilled into the remainder of the broken tap. Then…success! He plucked out the remnant of the fractured tap.

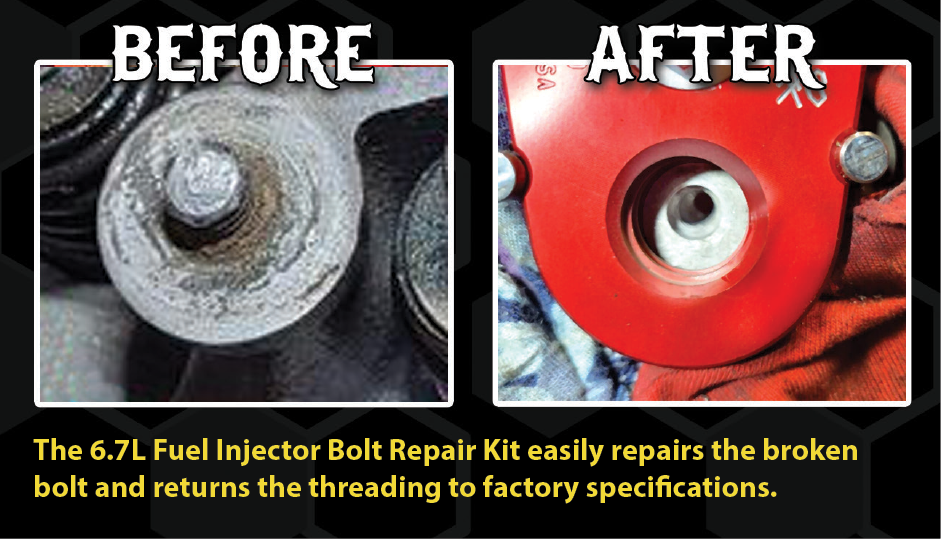

Since the initial botched repair attempt was over-drilled, it was now necessary to drill out the rest of the bolt, run a tap through to clean out the threads and then use a ProMAXX Tool Thread Repair Kit.

“After I removed the guide plate, I used a 10-millimeter tap to make a new thread pattern. It cut through that head like it was nothing.” McCauley said. “Using the provided insert tool and a drop of Loctite, it was easy to screw in the new thread insert.”

INSERTS ARE STRONGER THAN CAST IRON

The Cylinder Head Repair Kit comes with an insert tool, a ProDrill Gold SSSC345 bit, an extra-large ProBushing, a 10-millimeter tap, four black-oxide-coated steel inserts (not Helli-coil), one blind insert and a small bottle of locking fluid. The heavy-duty inserts are stronger than the original cast iron manifold material. The advantage of the inserts is that they are threaded on the insert tool and will not fall off during installation into the cylinder head.

“YOU’LL HAVE GREAT SUCCESS WITH THESE KITS IF YOU FOLLOW THE INSTRUCTIONS CAREFULLY,” MCCAULEY SAID. “START OUT DRILLING SMALL, TOGGLING THE POWER TO ESTABLISH A STARTING POINT. THEN, STEP UP TO THE NEXT DRILL BIT SIZE. BEFORE YOU KNOW IT, THE BROKEN BOLT IS TOAST.”

By the time the manifold portion of the truck repair was complete, the customer was so happy with their price that they spent even more money to have McCauley replace the power steering lines, brakes, starter and other items. The shop was able to up-sell its services and put more money in its pocket because it delivered value to its customer.

WELDING DOESN’T ALWAYS WORK“When you come across a job with 15 or so broken bolts, you aren’t going to be able to weld them all out 100 percent of the time,” McCauley said. “But, if you use the ProMAXX Tool kits right and take your time, you’ll always have success. That’s how you earn a reputation and make more money. Once your name is out there, the phone calls won’t stop.”

SEE HOW TECH QUICKLY REMOVES BROKEN TAP WITHOUT PULLING ENGINE

After using the Platinum Drill Bits, McCauley went to work with a reamer bit. Hot orange sparks shot from the bolt hole as he drilled into the remainder of the broken tap. Then…success! He plucked out the remnant of the fractured tap. See the article in AutoLink Magazine

TOOLING TO REPAIR BROKEN EXHAUST MANIFOLD BOLTS

ON KIT FIXES 20 ENGINES EXHAUST MANIFOLDS

BROKEN SCREW EXTRACTOR REMOVAL KITS

CYLINDER HEAD REPAIR KIT WITH THE BLIND PROSERT

PREMIUM PLATINUM DRILL BIT TOOLING OPTIONS

NEW AT PROMAXX

-

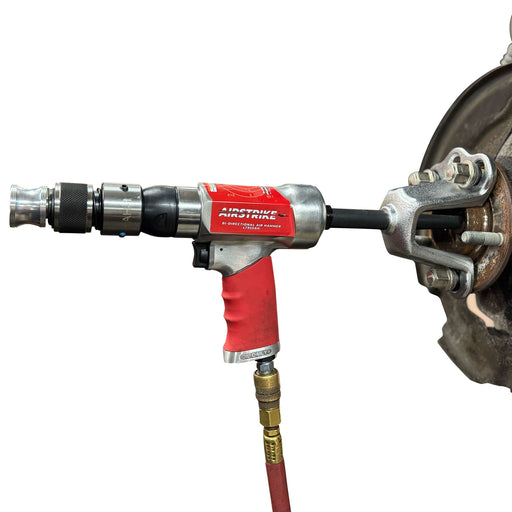

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Hold-A-Rotor® and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95Original price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment