How To Remove Broken Extractors and Repair Busted Bolts: Tools Used By Ford Tech

Broken extractors and busted bolts can cause concerns for mechanics and customers. With broken engine parts, repairs can be delayed and damages to vehicles can run costly. Using Platinum Drill Bits and the Exhaust Manifold Repair Kit from ProMAXX, mechanics are equipped with the tools to make repairs without risking damage to the vehicle’s parts. Here is how a Ford dealership mechanic used ProMAXX tool kits to get grueling repair jobs done.

Michigan Ford Dealership Uses Platinum & Gold Tooling Bits To Complete RepairsThe service department at a Ford Dealership in Michigan frequently fixes diesel engines tasked with hauling heavy loads. Located 45 miles northwest of Detroit, the dealership mechanics work on diesel engines that operate in harsh weather conditions. From highly-stressed farm trucks to worn transport vehicles, these experienced techs often struggle with broken bolts caused by Michigan’s dramatic seasonal swings.

Tom Easterwood is a diesel tech with more than 38 years of experience. He regularly repairs truck components, including every part from the front end to the back bumper.

“Up here, the weather affects engines in many ways,” Easterwood said. “We see lots of rusted studs due to corrosion caused by calcium chloride, which is put down on dirt roads to alleviate dust in the summer. Then, of course, we get the devastating rust buildup thanks to tons of winter road salt.”

Recently, diesel tech Joe Baker came across an exhaust leak on a 2008 Ford F250 6.4L Power Stroke V-8 diesel. He assessed the situation and deduced that it was due to a broken rear exhaust manifold stud.

“I began to drill the bolt so I could insert a square-tipped extractor,” Baker said. “But once I got the extractor in, it snapped off as soon as I turned it. I tried to use a torch to loosen it up a bit, but that didn’t help.”

Realizing this job just got a lot more complicated, Baker consulted with shop foreman Chris Lakso, who recommended that he use the ProMAXX Tool Rocky II Exhaust Manifold Repair Kit. This manifold repair kit is designed for Ford gas 4.6L, 5.4L and 6.8L engines as well as the Power Stroke diesel 6.0L and 6.4L engines.

“We picked up the updated exhaust manifold repair kit at a local vendor night a couple of years ago,” said Lakso. “Since then, we’ve used it many times. This kit is a time-saver and it helps reduce exhaust manifold repair costs for our customers. If we didn’t have a reliable tool to repair busted bolts right on the truck, we’d have to pull the cab and remove the cylinder head, which is a huge, expensive, and time-consuming ordeal.”

This is when Easterwood, the more experienced tech, took the job over. “Joe was having trouble with the repair,” said Easterwood. “So, I fastened down the Rocky II jig and attempted to drill out the broken bolt. But I ran into trouble. I spent hours drilling and all I had to show for it was five or six broken gold bits. I thought, "What's wrong with these things?”

At that point, they decided to call ProMAXX Tool Specialist Bill Lieb, who sold them the original kit. As luck would have it, Lieb and ProMAXX Tool founder Jeff Del Rossa were already in Michigan conducting tool demonstrations at several auto dealerships and independent shops. The pair quickly reset their GPS and arrived at the Ford dealership in less than an hour.

As soon as they got to the shop, Del Rossa went right to work to drill out the bolt. However, Del Rossa stopped and questioned, “Was this repair previously done somewhere else?” This is when Baker, the first tech to attempt the repair, walked by and mentioned the broken extractor, which the second repair team was completely unaware of.

“If I knew there was a broken extractor in that bolt, I would have taken a different approach to get it out,” said Easterwood. “Once we realized that, Jeff from ProMAXX brought out his Platinum Tooling (Drill) Bits and easily cut through both the bolt and extractor in less than 15 minutes.” With the proper tooling, the kit can easily complete a broken bolt repair and help rescue a previously botched job.

“The strength of Asian-made, tapered extractors is, at best, unpredictable,” Del Rossa explained. “Free-hand drilling with no guide plate puts the initial repair attempt drastically off center. And, square-tipped extractors only turn left. This causes inferior tools to deform the stud, complicating the repair.”

Del Rossa, who grew up in the auto industry while working at his father’s Ford dealership as a teenager, understands the needs of technicians and develops precision-specialty tools to help make shops more productive.

“When encountering a broken extractor, the first thing I do is use our Premium Platinum Tooling; consisting of specialized bits. The first step is to flatten the extractor and bolt remnants, removing any jagged edges that destroy drill bits,” he said. Del Rossa then goes to work with his platinum tooling that easily cuts through Rockwell 85 HRB steel, which is much harder than the extractor and broken stud. The combination of the kit’s precision guide plate, the end mill-flattened surface, and platinum tooling allows techs to quickly bore out both obstructions. Then, a ProMAXX® ProTap chases the threads and returns them to factory-new condition.

“When I talk to guys who work on a lot of diesels and EcoBoosts, I always recommend they pick up a Broken Extractor EZ Out Removal Kit when they purchase an Exhaust Manifold Repair Kit,” said Lieb, an experienced tool specialist. “We engineered special USA-made Platinum tooling bits and end mills (ProMill Center Cutting Carbide Endmill) to remove broken extractors, cobalt drill bits and even taps. It’s always wiser and more expedient to have a backup plan on hand in case you come across a previously unsuccessful repair.”

Easterwood explained that when faced with broken exhaust manifold bolts, he used to just try and weld them out. “In the past, welding has worked most of the time, but not 100 percent of the time. These kits are really well made, and they are 100 percent effective, making repair times extremely predictable,” he said.

“The jigs fit exactly, and the holes come out dead-center,” Easterwood said. “Now, the shop’s got both gold and platinum bits for our kits. Since we successfully used the exhaust manifold kit to turn this repair around, I’ll be sure to go to it next time we get a broken bolt. With the weather here in Michigan, the next time is probably right around the corner.”

How ProMAXX Tools Get The Job Done

Many shops have multiple ProMAXX Tool Exhaust Manifold Repair ProPlates on hand so they have the right tools to handle almost any repair right when they need it.

The Rocky II ProPlate makes techs more productive when working on Ford engines including: gas 4.6L, 5.4L and 6.8L engines, as well as the Power Stroke diesel 6.0L and 6.4L engines.

Broken extractors are no match for ProMAXX Tool’s Premium Platinum Tooling Drill Bits. They easily cut through Rockwell 85 HRB steel, which is harder than an extractor and broken stud.

When faced with broken studs, welding works sometimes but is not always reliable. ProMAXX Tool Kits are 100 percent effective, making repair times extremely predictable.

Precision-Designed Tools To Handle Difficult Repairs

NEW AT PROMAXX

-

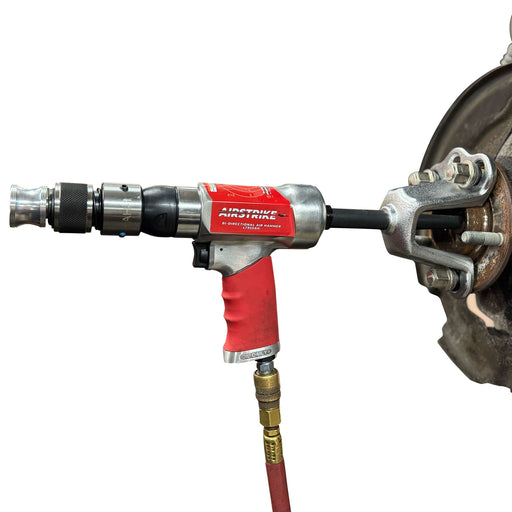

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Hold-A-Rotor® and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $329.95Original price$249.95 - $329.95$249.95 - $329.95Current price $249.95Original price $249.95 - Original price $329.95Original price$249.95 - $329.95$249.95 - $329.95Current price $249.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment