How To Easily Remove Stuck, Rusted Diesel NOx & Particulate Sensors Without Damaging The Threads

Recently, a third-party judging panel of industry experts selected the Shockit Diesel NOx & Particulate Sensor Removal Kit (Part # LT996D) from LTI Tools by Milton as the 2023 Specialty Tool Innovation Award Winner. This confirms that techs use this kit to increase productivity on sensor repairs making them faster and easier.

This unique air-hammer SHOCKIT-powered Sensor Removal Kit uses harmonic vibration to “shock” loose difficult-to-remove sensors, vastly shortening repair times.

SHOCKIT WORKS ON JUST ABOUT ANY ENGINE

The kit pops NOx sensors and particulate sensors (soot sensors) on Chevy Duramax, Dodge Cummins and Ford Power Stroke. It also pulls NOx sensors and lock nuts on Jeep and RAM ECO Diesel and removes Class 8 sensors including Kenworth, Caterpillar, Cummins, International, Detroit, Volvo engines and many more.

When a Long Island, New York construction company’s fleet vehicle started to run rough and burn through excessive amounts of fuel, they took the Ford F-550 to the experienced technicians at Northport Spring & Brake. After a quick diagnostic test, the answer was clear…a bad Diesel NOx Sensor was to blame.

THE MASTER TECH WANTED A BETTER TOOL

When Rob Limmer, an ASE-certified master technician with more than 30 years of experience took a look at the rusted-on sensor, he knew he needed a different tool for this application due to limited access for the repair.

So, he searched the web for a way to get it done with less hassle than with a conventional socket, ratchet or open ended wrench. He came across the SHOCKIT Diesel Sensor Removal Kit. After studying the online content and reviewing the video, Limmer took the next step.

Sean Hatch, the shop’s service writer, purchased the device. With the fleet truck sitting in his bay not earning any revenue, he picked the perfect solution to help him help his customer. The item shipped fast and arrived quickly to expedite the repair and move the asset from the shop, back onto the road and back to making the construction company money.

WHY ARE NOX SENSORS TOUGH TO PULL?

Over time, when a NOx sensor is coated in soot, it gives inaccurate readings. Also, it is exposed to abrasive gasses, allowing moisture to intrude, damaging the internal components. Due to constant temperature and environmental changes, the sensor rusts and seizes.

According to Limmer, the old-fashioned way to pull seized sensors involves using a torch to heat the frozen component to cherry-red. Then, a ratchet socket is used to muscle it out. After that, the threads are cleaned and a new sensor is inserted. This takes time, sweat and tons of patience.

“THERE ARE USUALLY A LOT OF DIFFERENT WAYS TO GET A JOB DONE. BUT, EVERY NOW AND THEN YOU COME ACROSS A NEW TOOL THAT HITS A HOME RUN,” LIMMER SAID. “THE POWERFUL IMPACT FROM THE UNIQUE AIR-HAMMER POWERED PUNCH ROD AND DIMPLED SOCKET ALLOWED ME TO EASILY SPIN THE STUCK SENSOR OUT.”

HOW DOES SHOCKIT TECHNOLOGY WORK?

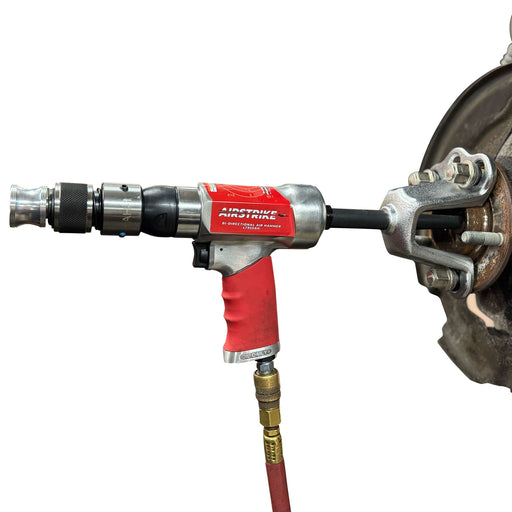

The secret to this kit is that it uses the amplified force and harmonic vibration of an air-hammer-powered punch drive to “shock” the sensor free. Experienced techs know how to remove corroded fasteners, applying tension and smacking them with a hammer. That usually does the trick.

With SHOCKIT, the system not only uses a hammer, it uses the constant impact effect of the hammer concentrated on a very small surface area, which translates to more power, less effort, and better results. Each of the five sizes of Shockit NOx Sockets are strong cast-hardened steel incorporating three driving ears with indexed holes for delivering maximum rotational force.

Each of the five sizes of Shockit NOx Sockets are strong cast-hardened steel incorporating three driving ears with indexed holes for delivering maximum rotational force.

Diesel Tech Kevin Miller uses the 7/8-inch Shockit socket to quickly pull a stuck sensor on a Ford Coyote 5.0L engine.

The socket’s inverted holes allow for tightening and loosening, working stubborn sensors back and forth. No back-and-forth cranking on a ratchet or pry-bar is necessary. This means they work great in tight spaces. The kit also includes 20mm, 22mm, & 27mm bottoming tap and dies for sensor and mounting hole threads.

“The entire job took me about 15 minutes to complete, and book time said it should take an hour,” Limmer. “After just a few uses, this tool will pay for itself. They really covered all the bases.”

Mike Powers is a master tech at Washington Ford in Western Pennsylvania. Recently, he snapped a cheap, non-Shockit socket in half while trying to ratchet out a stuck oxygen sensor on a Ford F-150.

CHEAP SOCKET TOOLS BREAK KNUCKLES

“I busted the cheap socket and banged my knuckles,” he said. It probably would have stripped the threads too. That’s the last time I use trash like that.”

A few days later Diesel Tech Kevin Miller was working on a 2014 Ford F-150 with a 5.0L Coyote engine. He realized that the Shockit LT1920 SAE Line Wrench Kit’s 7/8-inch socket would work on his Ford gas engine. This is a 13-piece kit that works on multiple gas engine fasteners like on AC, fuel systems, steering rack hydraulic fittings, ABS brake modules and more.

“We grabbed these kits for our shop because of their versatility, Miller said. “Yes, we can use them on diesel engines. But, we service a lot of other vehicles that they will work on. I’d recommend the Shockit sets for any shop. These kits nail it.”

WATCH SHORT NOX SENSOR PULLER VIDEO

See More Diesel Repair Kit Tooling For Technicians

Shockit Socket Diesel And NOx & Particulate Sensor Removal

Heavy Duty SAE & Metric Sockets Shockit XL Crows Foot Set

BULLIT Universal Broken Bolt Extractor

DEF Doser Decomposition Reactor Repair

NEW AT PROMAXX

-

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95Original price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95 -

Crankshaft Repair Kit Ford Coyote & EcoBoost - Harmonic Balancer Bolt. Avoid Engine Teardown

Part#: PMXCSR035KIT - ECOOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Ford 3.5 Ecoboost Harmonic Balancer Bolt Puller Kit: PMXCSR035KIT - ECO• Compatible with Ford 3.5L Bolt Part: HL3Z-6A340-A & F5RZ-6A340-B• May ...

VIEW MOREOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment