Different Types Of Taps & When To Use Them: Taper, Plug, Bottoming Tap, Spiral And Straight Flute Taps

Different Types Of Taps & When To Use Them: Taper, Plug, Bottoming Tap, Spiral And Straight Flute Taps

If you’ve worked on a car repair at home or in any automotive, industrial or fabricator shop before you may know a tap is a common yet overlooked hand tool. Machining technologies have advanced, and common taps have become more specific in use and in care. Learn about taps in their basic and complex forms and how they are used below.

WHAT ARE THE DIFFERENT GRADES OF TAPS?

Machine-Grade Taps Typically Perform the Best

First, breaking taps into three different layman type grades is essential to make sure you have the right tool for the right job. Machine grade, the best, most accurate and sharpest of the bunch, is the number one choice for any repair that calls for precision, quality, and productivity. Machine grade taps also demand a higher purchase price as they are cut and machined to precision tolerances that allow the tap to cut to a predetermined depth of thread. Loose fasteners will lose their holding strength, but a fastener that fits too tightly will fail to engage properly.

Machine grade taps are also capable of high machine speeds in CNC lathes and milling machines. They are used to cut multiple holes consecutively and at higher feed rates. In fact, holes per minute can last much longer holding an edge for continued use and repeatability.

Medium-Grade Taps For Multipurpose Use

Medium grade taps are often found in jobber warehouse-type stores and are of generally a good quality multi-purpose use. Best used in hand applications and where tap life and precision are not as important as availability and cost.

Entry-Level Grade Taps For Hand Applications

Quality entry-level grade taps are usually found in hardware stores and are best used for hand applications. However, they have a limited life and are less tolerant of the misalignment of the tap with the bore.

WHAT ARE TAPS USED FOR?

A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. Though this tool is most commonly used by machinists and engineers, automotive technicians may also have a tapping set in their toolbox. There are dozens of situations where having a solid knowledge and appreciation for the science behind tapping threads into a piece of machinery can prevent hours of troublesome work and hundreds of dollars in replacement parts.

Here is what you need to know about hand taps before using them:

WHAT ARE THE THREE MAIN TYPES OF TAPS?

So what are the different types of taps? There are three main taps types you should be familiar with and they are: Taper Tap, Plug Tap, and Bottoming Tap.

Understanding the different types of taps is crucial for anyone involved in vehicle repair, metalworking, machining, or DIY projects that require precise threading. Taps are tools used to create internal threads in holes, allowing screws or bolts to be securely fastened. There are three main types of taps that you should be familiar with: Taper Tap, Plug Tap, and Bottoming Tap. Each type serves a specific purpose and is designed to handle different stages of the threading process.

1. Taper Tap

Description:

Taper taps are characterized by their gradually increasing thread depth, typically starting with a significant taper of about 10 to 15 degrees. This design makes them easier to start in a pre-drilled hole.

Uses:

• Starting Threads: Ideal for beginning the threading process in a new hole.

• Blind Holes: Suitable for holes that do not go all the way through the material.

• Difficult Materials: Effective in harder materials where starting the thread can be challenging.

2. Plug Tap

Description:

Plug taps have a shorter taper, usually around 3 to 5 degrees, and are designed to follow the taper tap. They provide a balance between ease of threading and thread precision.

Uses:

• Continuing Threads: Used after a taper tap to deepen the thread.

• Standard Threading: Suitable for creating accurate threads in most applications.

• Through Holes: Effective in holes that extend through the material, allowing for better thread formation.

CHART SHOWING DIFFERENT TYPES OF TAPS

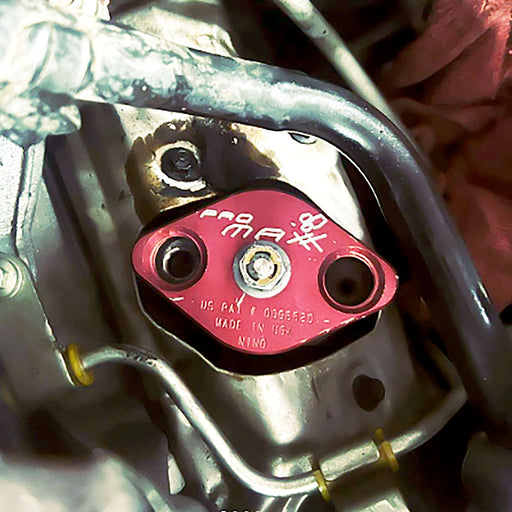

VIDEO: Using ProTap Bottoming Tap Chase Threads on Exhaust Manifold Bolt Repair

3. Bottoming Tap Works Best For Exhaust Manifold Bolt Repair

Description:

Bottoming taps have minimal or no taper, designed specifically to create threads all the way to the bottom of a blind hole.

Uses:

• Completing Threads: Used after taper and plug taps to fully form the thread at the base of the hole.

• Deep Blind Holes: Essential for ensuring complete thread engagement in holes that do not pass through the material.

• High-Precision Applications: Necessary in scenarios where full thread depth is critical for the integrity of the assembly.

Choosing the Right Tap for the Job

Selecting the appropriate tap type depends on the specific requirements of your project:

• For Starting Threads: Begin with a Taper Tap to easily initiate the threading process.

• For Continuing Threads: Use a Plug Tap to deepen the thread and improve accuracy.

• For Completing Threads: Finish with a Bottoming Tap to ensure threads extend to the bottom of the hole.

Spiral vs. Straight Flute Taps

Spiral Flute Taps:

• Great for softer metals.

• Effective chip evacuation.

Straight Flute Taps:

• Robust design with a thicker cross-section of the cutting edge.

• Effective for creating clean threads in hard materials.

Selecting The Most Effective Tap:

• For guided tapping with a guide plate and bushing, use a bottoming tap for aggressive, complete cutting.

• For freehand tapping, start with a taper tap, then progress to a bottoming tap for thorough cutting action.

Experienced Tech Uses ProTap to Restore Threading to Factory New Specs Then Securly Places Thead Insert

At ProMAXX Tool, we work with automotive technicians every day, providing them with the tools and the knowledge necessary to bring the science and precision of a machine shop to the repair bay at their shop. If you have any questions about using taps in an automotive application, give ProMAXX Tool’s repair consultants a call 24/7 @ 724-941-0941.

ProMAXX Tool's ProTaps are avalable in seven sizes ranging from 6mm x 1.0 to 3/8 x 16

NEW AT PROMAXX

-

Hold-A-Rotor and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Crankshaft Repair Kit Ford Coyote & EcoBoost - Harmonic Balancer Bolt. Avoid Engine Teardown

Part#: PMXCSR035KITOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Ford 3.5 Ecoboost Harmonic Balancer Bolt Puller Kit: PMXCSR035KIT - ECO• Compatible with Ford 3.5L Bolt Part: HL3Z-6A340-A & F5RZ-6A340-B• May ...

VIEW MOREOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

EGR Repair Kit Ford 6.7L Power Stroke 8mm - $200 Free Tech Support

Part#: PMXN200PRO-008Original price $74.95 - Original price $824.95Original price$74.95 - $824.95$74.95 - $824.95Current price $74.95Original price $74.95 - Original price $824.95Original price$74.95 - $824.95$74.95 - $824.95Current price $74.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment