HOW TO USE A BOLT EXTRACTOR PROPERLY

There are many different types of screw and bolt extractors on the market. Choosing the right one is critical to getting the job done more productively. Even more important, is using it correctly so that you can avoid breaking the extractor off inside the broken bolt or screw.

When you are attempting to remove a broken bolt using an extractor, you need to choose a broken bolt extractor that is the best fit for the job. The bolt or screw you are attempting to remove may be broken off above the mating surface, flush with the surface or below the surface. The bolt can be broken for a number of reasons. The bolt may have been extremely corroded leading to the head breaking off. You may have also used too much torque when removing the bolt (common when overusing your high-powered impact wrench). In a much more unfortunate situation, the threads of the bolt and the mating surface may have been compromised, usually due to two dissimilar metals fusing from chemical reactions, excessive heating and cooling or the bolt being installed with the wrong torque spec ratio.

CHOOSING AND USING THE BEST BROKEN BOLT SCREW EXTRACTOR

1.WHEN CHOOSING A BOLT EXTRACTOR, DO NOT PICK THE MOST CONVENIENT METHOD

The least expensive offshore broken screw extractor that you picked up at the value-home-center may only lead to disaster. You are already running behind on the job due to a broken bolt. Deciding to go with a lower quality solution to fix this problem can lead to a compounded issue when the hardened steel breaks along the shank during extraction. There are many styles of extractors available on the market from reputable American manufacturers. Check out our article, “which screw extractor should I use”. . ProMAXX Tool recommends the straight fluted extractor with a turn nut due to its resistance to deforming the broken stud or bolt while delivering an equal distribution of force and torque directly to the extractor. This Multi-Spline Screw Extractor is the only style of extractor that ProMAXX Tool uses in our exhaust manifold repair kits, due to its effectiveness, durability, and predictability on break-torque. Moreover, this style of extractor allows turning the bolt in either direction, easing the removal.

2.DRILL A HOLE AS DEAD-CENTER ACCURATE AS POSSIBLE

When you go to extract the screw or bolt, you are going to apply torque to a bolt that is already broken due to some sort of fragility or resistance. You will start the bolt extraction process by drilling a pilot hole. Start small, and work your way up to the largest gauge possible required for the extractor. Hammer in the extractor and begin turning it clockwise, then counter-clockwise. If the pilot hole is drilled off-center: (A) You will not be able to drill to a larger gauge without coming into close proximity to the threads. (B) When extracting, the applied force will be unevenly distributed to the extractor, causing unnecessary stress and increasing your odds of the extractor breaking. (C) Additional torque is introduced, which increases the probability of breaking the extractor.

At ProMAXX Tool, our ProKits allow technicians to bring the absolute dead-center accuracy of a machine shop right to the repair bay. Each ProPlate in the kits has been designed and manufactured for a unique bolt pattern. In addition, unlike other drill guides on the market, we take into consideration “tolerances.” Any “slop” in a drill guide, a drill guide bushing or even the fasteners connecting the drill guide will compound. That means, 0.01” offset here, 0.05” offset there, and you’re now drilling with an accuracy of +/- 0.06”, that’s nearly 1/16” of an inch.

GET LOW AND SPREAD OUT!

ProMAXX Tool recommends the straight splined extractor with a turn nut because it allows you to apply force as close to the broken bolt as possible, rather than distributing the load across a 1-2” shank. After tapping in the straight splined extractor, slide the turn nut down flush with the broken bolt. In addition, the straight splines will bite in at six points, rather than just four with cheaper extractors. Again, the advantage is distributing the load equally and broadly across every mating point.

As with any repair, the tool you use depends on the application. Many technicians have success welding a nut to broken bolts and can even get them out with a set of pliers. However, if time is money you need to use the most predictable, most productive and highest quality repair solution. At ProMAXX, we only design tools that can give technicians a return on their tooling investment in one to two uses. For more information on our latest tooling innovations, subscribe to our newsletter with the form below or contact us at 724-941-0941 promaxxtool.com.

CHECK OUT BROKEN BOLT EXTRACTOR TOOLING FROM PROMAXX TOOL

BEST BOLT EXTRACTOR

EXTRACTOR REMOVAL

RESCUE BIT REAMER

UPGRADE KIT TO EXTRACTORLESS

EXTRACTOR KING CASE STUDY

His go-to tooling for broken bolt and extractor removal is ProMAXX Tool’s Platinum Drill Bit Broken Screw Extractor Removal Kit.

BROKEN BOLT.DRILL GUIDE.REMOVING A BROKEN BOLTBOLT EXTRACTOR.SCREW EXTRACTOR.HOW TO USE A BOLT EXTRACTOR.HOW TO USE A SCREW EXTRACTOR.EZ OUT.EASY OUT

NEW AT PROMAXX

-

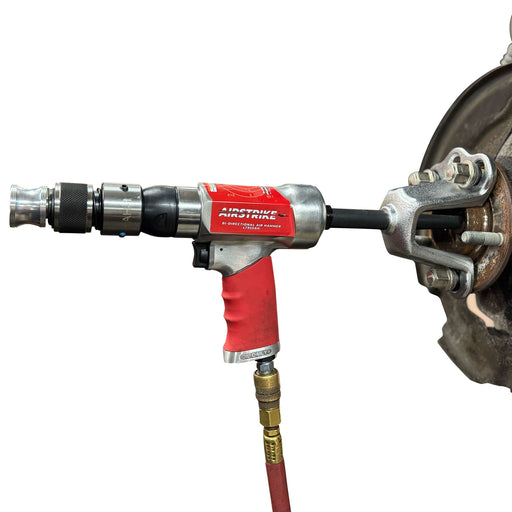

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Hold-A-Rotor® and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95Original price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment