What Techs Need To Know About Thread Repair Kits For Broken Bolt Repair

Thread repair kits have grown in popularity as replacement parts have become increasingly difficult to find. This is due to supply chain shortages and a rise in the cost of replacement parts. Thread repair kits allow for the removal and repair of damaged threads in a tapped hole. They can be replaced by chasing the threads using a thread chaser (a device designed to clean and restore factory threads) or installing an insert that contains new threads of the same size.

A thread repair kit is typically made up of a drill bit, tapping tool, an insertion tool and a threaded insert. An air or electric powered drill and a tap wrench are also required but are not usually standard in the kit. Thread repair kits are a cost-effective means of making a repair in a tapped hole without removing the part or parts containing the damage.

TYPES OF INSERTSOne of the most popular types of inserts is the Helicoil® insert. This insert consists of a small opening that engages with the insertion tool for an insert to be screwed into a tapped hole. The Helicoil® has a design of a tightly wound spring with a diamond cross-section. Though this type of insert may be simple to install, and relatively low-cost, it may not be as secure for a screw or bolt that will be under constant load (dimensional changes of the material it is installed in), high temperatures or torqued to a high level.

One of the most popular types of inserts is the Helicoil® insert This insert consists of a small opening that engages with the insertion tool for an insert to be screwed into a tapped hole. The Helicoil® has a design of a tightly wound spring with a diamond cross-section. Though this type of insert may be simple to install, and relatively low-cost, it may not be as secure for a screw or bolt that will be under constant load (dimensional changes of the material it is installed in), high temperatures or torqued to a high level.

Best application: Helical wire inserts are the way to go when cutting costs and minimizing space are priorities. In softer materials such as aluminum, titanium and magnesium alloys, they are especially helpful for making permanent strong threads and are ideally suited to lower heat and lower torque environments.

The Time-Sert® is another example of a thread repair kit that comes with an oversize drill bit relative to the nominal size of the tapped hole. This style insert is designed and equipped with accessories to drill and remove the old existing threads. The kit consists of a tap to create new threads, a counterbore drill to accommodate an insert flange, the insert which creates the new threads, the driver that inserts the Time-Sert® and a thread locking fluid to ensure the insert stays in place. Time-Sert® is a complete sleeve with threads on the outside diameter to be threaded into the hole and a stop flange to keep the sleeve from spinning inside the hole.

Best application: best in heavy wear, high vibration and high heat conditions, and hole depth is minimal.

The Helicoil® and Time-Sert® are easily found across the market. Although more expensive, the Time-Sert® is a more robust fix compared to the Helicoil® and depending on the criticality of the repair, may offer the right solution for the application. Though there are many options on the market, choosing the right insert depends on the difficulty of the repair, the application, and the cost of a replacement part. Overall, the Helicoil® is a less expensive alternative but can be difficult to install in tight spaces.

ProMAXX Prosert™ InsertsTh ProMAXX® blind hole insert is designed with a thick wall for durability and made from stainless steel or black oxide coating for corrosion resistance. This high-quality, precision-made insert can withstand extreme temperatures and high torque applications that are often seen in fleet heavy and light-duty trucks.

The advantage of the ProMAXX® engineered inserts is that they completely isolate the fastener from the parent material being machined. This isolation further reduces corrosion via chemical reaction (particularly in aluminum) and because they are steel, can be machined out and replaced if necessary, in the future. ProMAXX® ProSerts™ are high-quality precision tooling and when used with the ProMAXX® thread repair kit, can speed a repair with the results of stronger holding than the original factory hole tapped in aluminum.

Moreover, there are no additional steps required when machining to accommodate the ProSert™. Simply follow the included instructions to drill the hole, apply Loctite®, then twist in the insert with the included ProMAXX insert tool. No breaking of a tab or machining for a flange is required. Best application: The blind hole insert is particularly useful when fixing an exhaust manifold bolt that was over-drilled, drilled off-center, or worse, a punctured water jacket in the cylinder head.

A Nico Prosert is a threaded insert for 6.7L cylinder head restoration. It offers a permanent repair solution for Power Stroke fuel injector hold-down bolts that break off due to compromised threads and excessive corrosion.

Nino Proserts are heavy-duty inserts made of stainless- or high-strength carbon steel that have two pins to lock them in or a liquid thread lock that provides a positive lock for a permanent repair that is stronger than the original fastener itself. The thick walls are durable and constructed for corrosion resistance. These high-quality precision-made inserts can withstand the high manifold temperatures and duty cycles of the Ford 6.7L Power Stroke diesel engine.

Best application: Nino & Nico 6.7L Power Stroke thread repair inserts were each engineered with a specific application in mind. They are not a universal solution but offer the highest quality thread repair for two frequent and troublesome locations where threads need to be repaired and strengthened.

WHEN TO USE A THREAD REPAIR KIT IN THE AUTOMOTIVE REPAIR INDUSTRYThe dogma of using inserts to make a repair with the advent of newer machining capabilities and material technologies are a thing of the past. Making a repair that is better than factory specs is a good thing! When you combine that with high-quality precision inserts such as ProMAXX® ProSerts™, you get one that looks better too. Aluminum is the predominant material of choice because of the weight-saving factors and environmentally sound practices. Transmissions, oil filter adapters, oil pans, intake manifolds and many other automobile parts can suffer from threads that have been pulled out or a stubborn bolt that has galled into the parent material. Machine shop precision is the key to success in this equation and not as simple as running the tap through the hole. A thread repair kit will not only save a repair but ensures that the problem will not reoccur the next time the area is serviced.

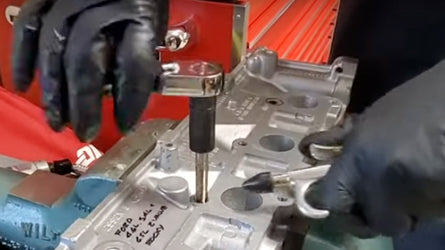

HOW TO USE MOST THREAD REPAIR KITS- Use a drill bit and bushing of the correct size to drill out the damaged threads.

- Tap the hole with a special thread to accept a threaded insert. Use the tap that is included in your thread repair kit.

- Using the insertion tool, screw the threaded insert into the hole below the surface of the part.

- Unscrew the tool used for insertion.

ProMAXX™ Tools exhaust manifold thread repair kit brings machine shop capability to the engine bay. Our kit includes a hardened steel precision bushing, machine-grade tooling bit, super sharp tap, and four 8mm x 125 black oxide hardened solid steel inserts. The thread repair kit restores stripped or damaged exhaust manifold mounting threads for better than factory spec repair. This kit works perfectly with any 200 Series ProMAXX™ ProKit and should be a staple item in all technicians’ toolboxes.

Essential Tools For Thread RepairNEW AT PROMAXX

-

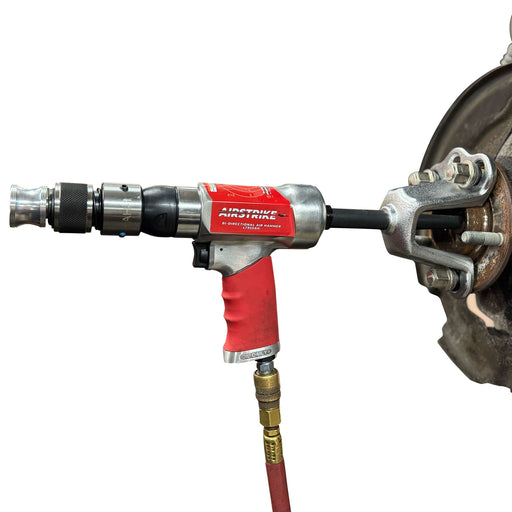

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95Original price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95 -

Crankshaft Repair Kit Ford Coyote & EcoBoost - Harmonic Balancer Bolt. Avoid Engine Teardown

Part#: PMXCSR035KIT - ECOOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Ford 3.5 Ecoboost Harmonic Balancer Bolt Puller Kit: PMXCSR035KIT - ECO• Compatible with Ford 3.5L Bolt Part: HL3Z-6A340-A & F5RZ-6A340-B• May ...

VIEW MOREOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment