Diesel Tech Uses Bullit To Slice Time And Cost: How To Remove Broken Bolts On Cat 3176C Diesel Engines

Heavy equipment technicians and owners often deal with broken bolts throughout the lifetime of the machines. Without precision-designed repair kits, repairs are difficult and lead to extended machine downtimes. Learn how diesel technicians are using the Bullit bolt tools and repair kits to get machinery repaired faster and easier.

Who Is Using the Bullit Universal Broken Bolt Extractor Tool Kit for Diesel Engine Repairs?

Justin Tarr is an experienced field service technician with Kozik Brothers, Inc. The company is an excavating and construction contractor with multiple pieces of heavy equipment in its inventory. Justin Tarr has vast experience working on a variety of diesel and gas engines for the business operations. He often encounters broken bolts on exhaust manifolds, intake valves and more.

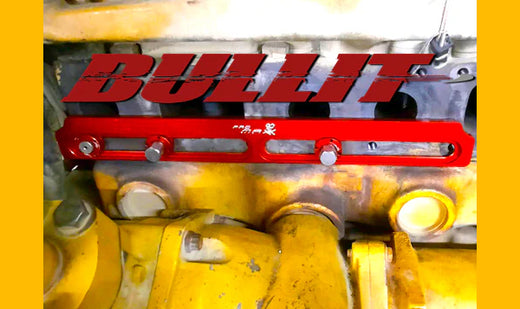

When Tarr came across busted intake mounting bolts on a Caterpillar 3176C Diesel Engine Compactor, he remembered seeing a live, in-shop demo of a tool designed to make engine repairs simpler and faster. So, he encouraged his company to acquire the Bullit® Exhaust Manifold Repair (EMR) Kit from ProMAXX Tool.

“When I opened the Bullit tool kit for the first time, it looked easy to use,” Tarr said. “Then, I watched a how-to video on the ProMAXX Tool YouTube channel. Once you get the bushings lined up, it’s simple to drill out the broken bolts. It works for linear, vertical, horizontal, and even diagonal bolt patterns.”

The BULLIT Universal Broken Bolt Extractor Kiot is Adaptable to Any In-Line Bolt Pattern for Cummins, Cat, Detroit Diesel, Freightliner and More

Why Is the Bullit Kit a Game-Changer for Techs?

As a trained diesel engine technician, Tarr knows it is essential to keep his company’s heavy equipment up and running. Every hour that a vehicle is in the shop means it is not out on the job performing its primary function.

“Repairing broken bolts like this can turn into a time-consuming, nightmare scenario,” Tarr said. “You may have to pull the head and send it out to a machine shop. It can take a full day to remove it. And, who knows how backed up the shop is? We may not get it back for days. This can cost thousands of dollars and extend equipment downtime.”

According to Tarr, thanks to the Bullit, it took him less than four hours to drill, tap, and restore two broken studs on the head and two more on the Caterpillar 815 F Diesel’s intake.

“WE SAVED TIME AND MONEY ON THE VERY FIRST REPAIR,” TARR SAID. “IF YOU CAN PAY OFF THE COST OF A TOOL WITH ONE REPAIR, IT’S WORTH KEEPING ON YOUR SHELF.”

What Kind of Support Does ProMAXX Tool Provide?

Tarr also appreciates the customer service he received from ProMAXX Tool. He believes the ProMAXX team brought a family experience to the relationship. “We are passionate about what we do,” said ProMAXX Tool Advisor Kelly Schreffler. “We go above and beyond what customers expect. And we provide free, 24-7 customer support.”

Because Tarr was at a worksite near ProMAXX Tool’s Pittsburgh, Pennsylvania headquarters, Schreffler was able to go out to the field to personally deliver extra drill bits to the technician. While she was there, she proactively showed Tarr another diesel engine tool kit she thought he may need in the future.

What Makes the Bullit Kit So Precise?

Bullit has adjustable carriages that configure the jig to the exact overlay of nearly any linear bolt pattern, eliminating manufacturing machine intolerances. The kit comes with three fasteners that lock the sliding carriages down to replicate the bolt pattern precisely. This ensures precision and alignment for perfect perpendicularity and spot-on center drilling.

It ships completely as an Extractorless™ repair system. Machine-shop-grade drill bits, along with tap and guide bushings, eliminate the risk of a broken extractor. The Bullit all-in-one adaptable kit allows for easy repairs on exhaust manifolds, intake manifolds, water pumps, valve covers, oil pan bolts and almost any other application involving a linear bolt pattern.

There are six different size versions of the Bullit kit ranging from 8mm-125 to 12mm-175. Bullit even works on vintage engine applications that use 3/8-inch bolts/studs, such as the Chevy 350, or Ford 460. The repair system was engineered to service many different engine types: Ford, GM, Dodge, Caterpillar, Cummins, Detroit Diesel, International, John Deere, Kubota, Volvo and vintage engine applications that use 3/8-inch bolts/studs.

What Other Diesel Kits Are Offered by ProMAXX Tool?

ProMAXX Tool produces a wide variety of repair kits designed specifically for diesel engines. These include exhaust gas recirculation (EGR) repair kits for the Ford 6.7L Power Stroke Diesel, and Mack MP8 and Volvo D13 Diesel Engines. Additionally, the company offers kits to repair Ford 6.4L Power Stroke Turbo Y Pipes and Ford 6.7L Diesel Fuel Injector Hold Down Bolts.

There are also tool kits engineered to assist in repairing broken exhaust manifold bolts on the GM 6.6L Duramax Diesel and Duramax Turbo Pedestal as well as the Ford 6.7 Power Stroke. Plus, the versatile and adaptable Bullit Collection provides for precise repairs on many different gas and diesel engines.

Ben Patton works with Tarr repairing diesel engines for Kozik Brothers, Inc. “If you’re trying to drill out broken bolts freehand and you go off-center, there’s no going back,” he said. “I’d recommend the Bullit to other diesel technicians because of its ease of use and the time savings it delivers. The advantages of using the Bullit tool kit are well worth the cost of the tool.”

Bullit has adjustable carriages that configure the jig to the exact overlay of almost any linear bolt pattern

Thanks to the Bullit bolt repair kits, it only took Tarr half a day to drill out two studs on the head and two more on the Caterpillar 815 F Diesel’s intake.

Experienced diesel techs Justin Tarr and Ben Patton say the Bullit’s ease of use and its time savings are well worth the cost of the tool kit.

We are passionate about what we do,” said ProMAXX Tool Expert Tool Advisor Kelly Schreffler. “We go above and beyond to exceed customer's expectations.”

BULLIT BOLT REPAIR KITS ADAPT TO THESE DIESEL ENGINE MODELS & MORE

General Motors

Ford Motor Company

Power Stroke

Cummins Diesel

Caterpillar Diesel

Intrnatnal Trucks

Volvo Engines

Dodge Engines

NEW AT PROMAXX

-

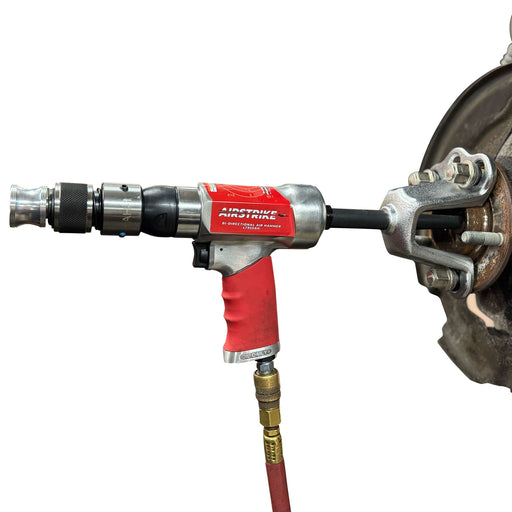

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Hold-A-Rotor® and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95Original price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment