How To Remove A Broken Exhaust Manifold Bolt: Welding Vs Drilling

This article breaks down the pros and cons of welding and drilling out broken exhaust manifold bolts, the level of experience each method requires, and the average success rate with both repair methods.

At ProMAXX Tool, we do not compete with the technique used to weld onto a broken exhaust manifold mounting bolt, we actually complement it. You may find this surprising, but just like you do every day, you diagnose problems and determine the correct approach and application of the tool or tools to make the most effective and efficient repair. After all, a flat rate doesn’t pay the bills, your expertise and efficiency do.

In the case of a broken exhaust manifold bolt, welding is an option, but not the only option... and some technicians rely on this single approach. We all know that one approach does not fit all applications so the application is the driver for this repair. Completing the repair in minutes or hours depends on which process you use to determine the method you use.

We know a thing or two about broken bolts because we work with technicians every day, developing tools that will boost their productivity. Moreover, our founder continues to remove broken bolts in dealerships and shops around the USA. He stopped counting at his 500th removal, just over three years ago. A broken bolt is one of the most frustrating things a technician is going to experience; in fact, it’s often avoided. When a technician comes across his first broken bolt, a quick Google search will most likely suggest the two options:

A MiG welder is the preferred tool for this job, but a stick welder, depending on where the break occurred (depending on the application: above, below, or flush with the cylinder), may also do the trick.

To start, select a nut or flat washer with an inner diameter roughly the size of the stuck threaded bolt. Place the flat washer and/or nut on the bolt and weld the inside of the nut to the broken top of the bolt. Then use a wrench to remove the nut and bolt together. Some technicians avoid the washer/nut combination altogether and simply “build” the weld creating a custom-fitted bolt that once above the surface of the head can be removed later. The welding process can be lengthy; the remnant needs to be cleaned in order for the weld to adhere, the temperature needs to be right in order to avoid burning the head and the steel you are welding to needs to be understood. For example, titanium alloy bolts found in most turbocharged engines take a great deal more heat to fuse to and much greater caution. Plus, getting a welding head into limited access, low-vision areas presents another set of challenges. Lastly, welding is not 100 percent effective in every situation. Just like other repairs, not any one solution works universally across all situations - again application.

- Requires a solid knowledge of welding and heat transfer

- Not 100 percent effective

- Can be time-consuming with equipment set up, heating & cooling and multiple attempts

- Modern engines contain a lot of dissimilar metals, which can make getting welds to stick very difficult

EXPERIENCE REQUIRED:

Moderate – MiG welding, metalworking

Drilling out a broken stud or bolt can be an intimidating task for some technicians, especially if the bolt is of a smaller diameter, as in the case of an exhaust manifold bolt (8MM) and a cold reminder that there is only a few thousandths of an inch of cast aluminum web separating the water jacket from the manifold bolt. The traditional method includes taking a punch and creating a divot (or center point) on the broken bolt surface, drilling a pilot hole freehand, hammering in an easy-out extractor, then attempting to back the bolt out. Even the greenest technician can manage this task, however, it can come with a series of things that can go wrong or create a bigger mess than when you started.

The most common issue comes from using cheap materials and off-the-shelf drill bits which can lead to off-center drilling. Walking drill bits and extractors can break and lengthen the repair cycle and rob your productivity and profitability. Lastly, drilling free hand and off-center introduces a torque moment at the center of the bolt that increases the energy required to remove the broken remnant, often exceeding the torque specs of the extractor.

Make sure to use ProDrill Platinum or Micro-Edge Gold Drill Bits for the broken stud and bolt removal.

BROKEN EXHAUST MANIFOLD BOLT REPAIR MADE EASY

NEW AT PROMAXX

-

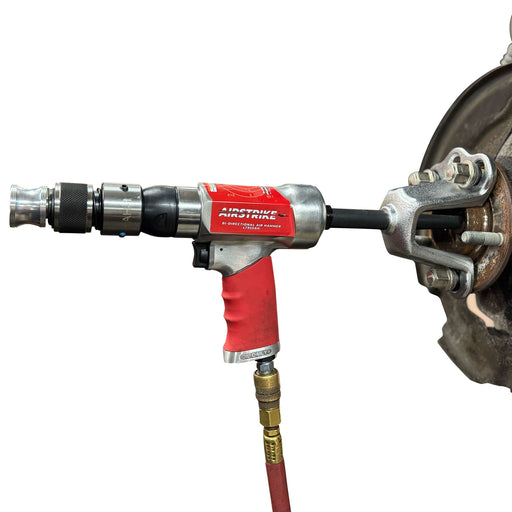

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Hold-A-Rotor® and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95Original price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment