Should You Use Anti-Seize On Exhaust Manifold Bolts Before Putting Them Back Into The Engine Head?

One question that is frequently debated by automotive technicians is,“do you put anti-seize on exhaust manifold bolts before putting them back into the engine head?”

We’re going to break down the pros and cons of using compounds and grease like high temperature anti-seize Loctite on your bolts and studs between repairs or maintenance. We will also weigh the key points of using the anti-seize lubricant after you remove, extract and replace fractured exhaust bolts.

There Are Numerous Anti-Seize Products On The Market

Each of these products has a special use and application. For example, automotive formulas may contain aluminum, copper and graphite which are combined with grease. These formulas work great in high temperatures with copper and graphite combined with high-quality grease, for example, on hot engine fasteners and bolts.

However, it is important to note that these additives will react harshly with moisture and wreak havoc – so avoid using them on marine engines at all costs! There are marine formulas of anti-seize that will have a rubber-cement type base which are crafted to prevent the corrosive effects of water and metal interaction. These marine-based formulas unfortunately do not have a high heat tolerance, so in areas such as exhaust manifold studs or turbocharger mounts, they would be very ineffective.

Consider The Temperatures The Exhaust Manifold Is Exposed To

On average, an exhaust manifold on gas and diesel engines will reach temperatures as high as 800 - 900 degrees under a medium load. The exhaust can reach 1,000 - 1,200 degrees under a heavy load and even higher on integrated turbochargers and at high throttle. Different formulas are engineered to withstand different temperature levels. Some anti-seize formulas will simply evaporate once the exhaust reaches these peak temperatures.

Which Type Of Anti-Seize Should I Use?

- Silver Grade Anti-seize:Fortified with graphite and metallic flake. Inert and will not evaporate or harden in extreme cold or heat. Can withstand temperatures up to 1600°F.

- Copper-based anti-seize:Fortified with copper and graphite in a grease. These can withstand temperatures up to 1800°F.

- Nickel Anti-seize: Copper-free.Recommended for stainless steel and other metals. These can withstand temperatures up to 2400°F.

OUR TWO CENTS:

Utilizing the correct, best anti-seize compound for exhaust manifold bolts can be an excellent way to prevent seizing, galling, and corrosion in areas that are regularly exposed to high temperatures. They are rust and corrosion inhibitors that can give you the upper hand the next time you remove your exhaust manifold. Just consider the application. If you are reusing exhaust manifold bolts (which we don’t recommend), apply a metal fortified anti-seize to your manifold bolts.

If you’ve just removed the broken bolts and are ready to complete the repair, chase the threads clean and use fresh OEM bolts for best results. Although there’s no real need for applying anti-seize, it can rarely hurt as these types of repairs are often done several times throughout the life of the vehicle and with a lucky draw of the card, you might just be the one to do it again.

60-SECOND EXHAUST MANIFOLD BOLT REPAIR VIDEO

BROKEN EXHAUST MANIFOLD BOLT REPAIR KITS: FORD, GM, DODGE

FORD GAS & DIESEL EXHAUST MANIFOLD BOLT

DODGE/RAM 6.4L HEMI BROKEN EXHAUST MANIFOLD BOLT REPAIR KIT - CHAD

DODGE HEMI 5.7L, 6.1L EXHAUST MANIFOLD BOLT

1 KIT = 20 ENGINES: FORD, GM DODGE BROKEN BOLTS

ANTI SEIZE.MANIFOLD BOLTS

NEW AT PROMAXX

-

Ford 6.7L Power Stroke Fuel Injector Puller Air Hammer Powered

Part#: PMXPWP900BPROOriginal price $89.95 - Original price $549.95Original price$89.95 - $549.95$89.95 - $549.95Current price $89.95Original price $89.95 - Original price $549.95Original price$89.95 - $549.95$89.95 - $549.95Current price $89.95 -

Dodge, Ram, Jeep, Fiat 3.0L V-6 EcoDiesel Fuel Injector Puller Air Hammer Powered

Part#: PMXPWP910PROOriginal price $89.95 - Original price $549.95Original price$89.95 - $549.95$89.95 - $549.95Current price $89.95Original price $89.95 - Original price $549.95Original price$89.95 - $549.95$89.95 - $549.95Current price $89.95 -

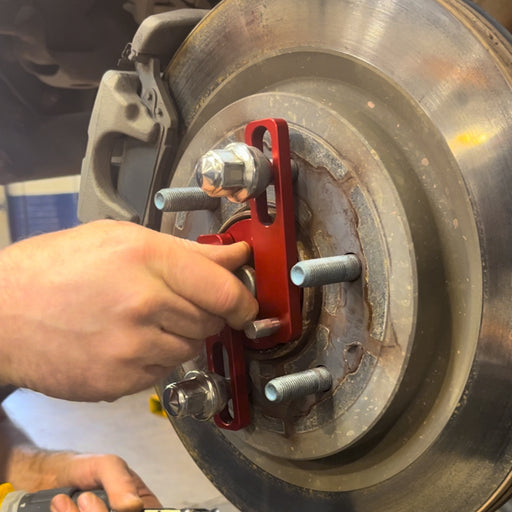

Hold-A-Rotor and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

SAVE: 13%

Ford F-150 Rear Axle Repair Kit For 2021–2023 Trucks w/ Trailer Tow Max Duty Package & 9.75-inch Heavy-Duty Axle

Part#: PMXFRA500PROOriginal price $399.95Original price $399.95 - Original price $399.95Original price $399.95Current price $349.95$349.95 - $349.95Current price $349.95Original price $399.95Original price $399.95 - Original price $399.95Original price $399.95Current price $349.95$349.95 - $349.95Current price $349.95SAVE: 13% -

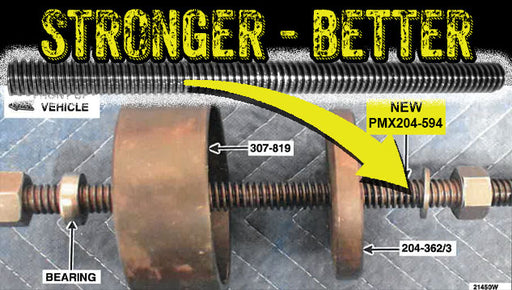

Forcing Screw Alternative to Ford 2020-2022 Explorer Recall Special Service Tool part# 204-594 "Thunderbolt"

Part#: PMX204-594Original price $0.00 - Original price $0.00Original price $0.00$149.95$149.95 - $149.95Current price $149.95Original price $0.00 - Original price $0.00Original price $0.00$149.95$149.95 - $149.95Current price $149.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.