Let’s Put The Power Back Into The Power Stroke

A truck sitting in the shop doesn’t do any work. The most common problems techs run into when working on Ford Power Stroke engines include broken bolts on the EGR Mounting Tube, Busted Fuel Injector Hold Down Bolts, Snapped Exhaust Manifold Studs and Stuck Fuel Injectors. ProMAXX Tool has an entire lineup of tech-tested specialty tool kits that shorten repair times, reduce costs and make Power Stroke mechanics more productive.

LET’S PUT THE POWER BACK INTO THE POWER STROKE

A truck sitting in the shop doesn’t do any work. The most common problems techs run into when working on Ford Power Stroke engines include broken bolts on the EGR Mounting Tube, Busted Fuel Injector Hold Down Bolts, Snapped Exhaust Manifold Studs and Stuck Fuel Injectors. ProMAXX Tool has an entire lineup of tech-tested specialty tool kits that shorten repair times, reduce costs and make Power Stroke mechanics more productive.

Combine & Save Between $100 & $250 New Power Stroke Packages

Broken Egr Mounting Tube Bolt • Broken Fuel Injector Hold-Down Bolt Broken Exhaust Manifold Bolt • Quickly Pull Power Stroke Fuel Injectors

Power Stroke Charlie: Hold Down Bolt Prokit Plus & Fuel Injector Puller

Power Stroke Bravo: Hold Down Bolt Prokit & Fuel Injector Puller

Power Stroke Alpha: Egr Tube Mounting Bolt & Fuel Injector Puller

Power Stroke Power: Egr Bolt, Hold Down Prokit, Exhaust Manifold Bolt

Egr Mounting Tube Bolt

Fuel Injector Bolt

6.7l Exhaust Manifold Bolt

Fuel Injector Seat Restorer

Power Stroke EGR Kit

Fuel Injector Bolt Video

Exhaust Manifold Video

Pull Fuel Injector Video

Bullit® Universal Adaptable Broken Bolt Extractor Kits

Universal BULLIT®: most versatile, most precise tool engineered for broken bolts, including exhaust & intake manifold, oil pan, valve cover etc. One kit, unlimited possibilities. BULLIT® has adjustable carriages that allow the tool to be configured to the exact bolt pattern of just about any linear bolt pattern, eliminating machine tolerances. Built to service virtually anything including import engines, vintage engines including and not limited to to Ford®, GM®, Dodge®, and even heavy-duty class 8 engines such as Volvo®, Caterpillar®, Cummins®, Detroit Diesel®, International®, John Deere®, Kubota®, etc. Bullit® ships complete as an Extractorless™ device; machine-shop-grade drill bits, tap and guide bushings eliminating the risk of a broken extractor.

Bullit® - Universal Bolt Extractor

Bullit® - Universal Bolt Extractor

Bullit® - 8-Mm Bolt Extractor

Read Informative Articles on Ford Power Stroke Diesel Repairs

Ford Tech Removes Broken Extractor

FORD TECH USES PLATINUM DRILL BITS AND EXHAUST MANIFOLD REPAIR KIT: HOW TO REMOVE BROKEN EXTRACTORS AND REPAIR BUSTED BOLTS

Read More

Many shops have multiple ProMAXX Tool Exhaust Manifold Repair ProPlates on hand so they have the right tool to handle almost any repair right when they need it.

The Rocky II ProPlate makes techs more productive when working on Ford gas 4.6L, 5.4L and 6.8L engines as well as the Power Stroke diesel 6.0L and 6.4L engines.

Broken extractors are no match for ProMAXX Tool’s Premium Platinum Tooling Drill Bits. They easily cut through Rockwell 85 HRB steel, which is harder than an extractor and broken stud.

When faced with broken studs, welding works sometimes, but not 100 percent of the time. ProMAXX Tool Kits are 100 percent effective, making repair times extremely predictable.

“We picked up the updated exhaust manifold repair kit at a local vendor night a couple of years ago.” said Lakso. “Since then, we’ve used it many times. This kit is a time-saver and it helps reduce exhaust manifold repair costs for our customers. If we didn’t have a reliable tool to repair busted bolts right on the truck, we’d have to pull the cab and remove the cylinder head, which is a huge, expensive, and time-consuming ordeal.”

This is when Easterwood, the more experienced tech, took the job over. “Joe was having trouble with the repair,” said Easterwood. “So, I fastened down the Rocky II jig and attempted to drill out the broken bolt. But I ran into trouble. I spent hours drilling and all I had to show for it was five or six broken gold bits. I thought, what’s wrong with these things?”

At that point, they decided to call ProMAXX Tool Specialist Bill Lieb, who sold them the original kit. As luck would have it, Lieb and ProMAXX Tool founder Jeff Del Rossa were already in Michigan conducting tool demonstrations at several auto dealerships and independent shops. The pair quickly reset their GPS and arrived at the Ford dealership in less than an hour.

As soon as they got to the shop, Del Rossa went right to work to drill out the bolt. However, Del Rossa stopped and questioned, “Was this repair previously done somewhere else?” This is when Baker, the first tech to attempt the repair, walked by and mentioned the broken extractor, which the second repair team was completely unaware of.

“If I knew there was a broken extractor in that bolt, I would have taken a different approach to get it out,” said Easterwood. “Once we realized that, Jeff from ProMAXX brought out his Platinum Tooling (Drill) Bits and easily cut through both the bolt and extractor in less than 15 minutes.” With the proper tooling, the kit can easily complete a broken bolt repair and help rescue a previously botched job.

“The strength of Asian-made, tapered extractors is at best, unpredictable,” Del Rossa explained. “Free-hand drilling with no guide plate puts the initial repair attempt drastically off center. And, square-tipped extractors only turn left. This causes inferior tools to deform the stud, complicating the repair.”

Del Rossa, who grew up in the auto industry while working at his father’s Ford dealership as a teenager, talks the language of techs and develops precision specialty tools to help make shops more productive.

“When encountering a broken extractor, the first thing I do is use our Premium Platinum Tooling; consisting of specialized bits. The first step is to flatten the extractor and bolt remnants, removing any jagged edges that destroy drill bits,” he said.

“When I talk to guys who work on a lot of diesels and EcoBoosts, I always recommend they pick up a Broken Extractor EZ Out Removal Kit when they purchase an Exhaust Manifold Repair Kit,” said Lieb an experienced tool specialist. “We engineered special USA-made Platinum tooling bits and end mills (ProMill Center Cutting Carbide Endmill) to remove broken extractors, cobalt drill bits and even taps. It’s always wiser and more expedient to have a backup plan on hand in case you come across a previously unsuccessful repair.”

Easterwood explained that when faced with broken exhaust manifold bolts, he used to just try and weld them out. “In the past, welding has worked most of the time, but not 100 percent of the time. These kits are really well made, and they are 100 percent effective, making repair times extremely predictable,” he said.

“The jigs fit exactly, and the holes come out dead-center,” Easterwood said. “Now, the shop’s got both gold and platinum bits for our kits. Since we successfully used the exhaust manifold kit to turn this repair around, I’ll be sure to go to it next time we get a broken bolt. With the weather here in Michigan, the next time is probably right around the corner.”

ROCKY. IIPLATINUM TOOLIN.PLATINUM BITS .EZ OUT EXTRACTOR.EXHAUST MANIFOLD REPAIR4.6L. 5.4L . 6.8L . 6.0L . 6.4L.FORD.BROKEN EXTRACTOR

What Tech Needs to Know About Thread Repair Kits

WHAT TECHS NEED TO KNOW ABOUT THREAD REPAIR KITS

Read More

- Use a drill bit and bushing of the correct size to drill out the damaged threads.

- Tap the hole with a special thread to accept a threaded insert. Use the tap that is included in your thread repair kit.

- Using the insertion tool, screw the threaded insert into the hole below the surface of the part.

- Unscrew the tool used for insertion.

How to Replace an EGR Cooler

HOW TO REPLACE AN EGR COOLER

Read MoreHOW TO REPLACE AN EGR COOLER

Replacing an EGR Cooler can be a discouraging but necessary task. Plugged EGR coolers are the leading cause of P0401 EGR insufficient flow codes. With a damaged EGR Cooler, the EGR system has a higher combustion temperature and poor performance. Follow these steps to ensure an easy replacement.

LOCATE THE EGR COOLER

The EGR cooler is located on top of the passenger side valve cover. Besides the EGR pipes, only the air filter lid and intake tube need to be removed.

DRAIN THE COOLING SYSTEMS

Place a drain pan below the radiator. Radiators have a petcock (shut-off) valve for draining or removing the lower radiator hose. Be sure to loosen the coolant cap to allow for airflow, turn the petcock valve and drain the cooling system. Both cooling systems need to be drained. The 6.7 has two systems. One for the intercooler and EGR valve and one for the engine and EGR cooler.

DISCONNECT THE PCM AND EGR COOLER FASTENERS

Next disconnect the power-train control module (PCM), unbolt the bracket and remove it. Remove the inlet and outlet hoses from the EGR cooler. Squeeze and loosen the clamp and position it higher on the hose. Remove the EGR cooler and gaskets. Then remove the plastic intake tube and filter cover. On the front exhaust crossover pipe, unbolt all bolts and place it out of the way with the temp sensor remaining plugged in.

UNBOLT THE EGR TUBE (LONG PIPE)

On the tube running from the EGR cooler to the exhaust manifold, locate the two bolts facing upwards on the up-pipe of the manifold. Spray these liberally with your favorite penetrating oil (try ProMAXX Bolt Blaster). Let the oil soak and then use patience while turning each bolt out.

Note: Should the bolts break, don’t panic. The Nino ProKit by ProMAXX was engineered to extract the broken EGR bolts quickly and easily with machine shop grade tooling; then it uses stainless steel inserts which will provide a permanent, on the truck repair with a stronger tensile strength than the OEM connection.

Remove the two push pins holding the passenger side injector insulator to the EGR cooler housing. Expel the two thrust pins holding the traveler side injector separators to the EGR cooler lodging.

UNPLUG THE FRONT OF THE EGR COOLER HOUSING WITH THE CONNECTORS AND VACUUM LINES

On top of the cooler, detach all bolt attachment nuts. On the EGR cooler housing, pull up. It rides on dowels and is often difficult to break free from the manifold runners of the valve cover/intake.

The cooler is rather easy to disassemble from here. Begin by removing the bolts that connect the front housing to the cooler's foundation. Except for one bolt, the front housing bolts are not the ones at the top, but rather the ones at the stage below. Force the EGR cooler core out of the base is the final disassembly phase. Carefully pry it out of the front being cautious to not damage the sealing surface. Fill both cooling systems.

Hit each rod and stand on the base until the core becomes loose enough to remove and clean it. Remember to remove and replace the EGR Cooler seals on the backside.

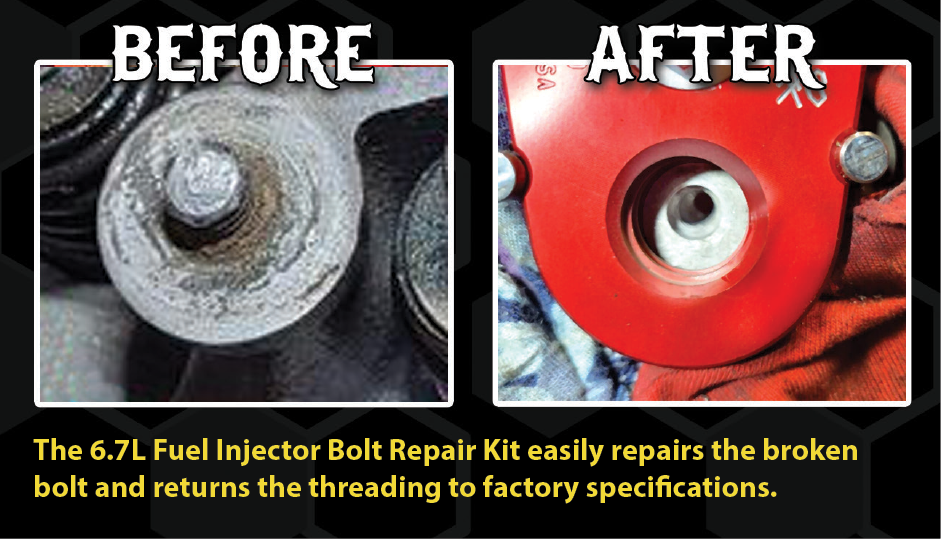

FUEL INJECTOR BOLT REPAIR KIT MAKES THE FIX

INSTALL THE EGR COOLER

If the entire system is cleaned and equipped to go, before installing the EGR cooler, lubricate the seals you hooked up and deploy the inner metal gasket first on to the foundation. Push the core down into the foundation with something flat when you reach the seals to finish moving it into the base. Reinstall your cooler EGR now. Install lower hose or close the petcock then install the refill the radiator with coolant. Finally, reconnect the negative battery cable and tighten it.

To see a video of the EGR cooler replacement in action, check out:

Detailed explanation of how to replace the EGR cooler core on 11-16 Ford 6.7l Diesel. Plugged EGR coolers are the leading cause of P0401 EGR insufficient flow codes. Over time the coolers plug with soot and prevent exhaust gasses from flowing through. Always follow OE procedures if you are unsure of what to do.

Videos courtesy of Nathan Reust from In The Shop.

If the EGR tube bolts break during the replacement, you can also check out In The Shop’s repair video:

In this video I review and show the process of the ProMaxx tools NINO tool kit. This kit was very well thought out and should save a ton of time especially if you work on the 6.7 Powerstroke often.

EGR Replacement Tools and Kits

ProMAXX® has done research on thousands of EGR repairs and has taken the guesswork out of the job. If you have questions on what tooling you need for your next repair, give the experts at ProMAXX® a call at 724.941.0941.

Three Tools Power Stroke Techs Should Own

THREE TOOLS EVERY POWER STROKE TECHNICIAN SHOULD OWN

Read MoreAutomotive and diesel technicians need a variety of tools to get cars, trucks and fleets back on the road and running at peak performance. Today, technicians are trained to use tools for diagnostic testing, electrical systems, and engine and exhaust repair. Along with these skills, technicians must learn how to get the jobs done efficiently.

When technicians are productive and avoid letting vehicles sit in the bay for days, their service managers will compensate and reward them. Some shops are paid a flat rate for work, while others will bill hourly. Either way, it pays for technicians to invest in having the right tool for the job. Here are three tools that ProMAXX Tool suggests every auto and diesel technician have in their toolbox.

1.FORD INTEGRATED DIAGNOSTIC SYSTEM (IDS)

The Ford Integrated Diagnostic System (IDS) can give complete diagnostic coverage of almost any Ford, Lincoln and Mercury vehicle. This tool gives technicians the ability to perform module reprogramming, key programming and a ton of other functions. It can be found at most Ford dealerships, making it a staple if your shop regularly works on Ford trucks and vehicles.

According to the National Institute for Automotive Service Technicians , having strong diagnostic skills and knowing how to use a tool like the Ford IDS can help you attain one of 40 different ASE Certifications. Technicians experience benefits for their career and compensation with these certifications. Not to mention, they are better equipped to handle Ford maintenance and repairs.

2.EGR TUBE REPAIR KIT

Diesel trucks have remained popular in both commercial fleets and for personal use. Their horsepower, torque and efficiency have made them an ideal investment when you need to haul heavy payloads and put a lot of miles on the engine.

Newer laws have required these trucks to introduce systems like the Exhaust Gas Recirculation (EGR) system. EGR is a nitrogen oxide emission reduction system that recirculates a portion of exhaust gas back into the engine. The system reduces peak temperatures in the cylinder head.

The connection point where the EGR tube meets the engine head is prone to high temperatures and heavy corrosion. Therefore, when the tube is disconnected, there is always a likelihood that the bolts connecting the EGR tube can snap off.

A popular choice for many Ford Diesel Technicians is the Nino ProKit. This kit allows the technicians to drill these bolts out, over-drill into the manifold, then screw in a stainless steel insert that will handle temperatures that will not corrode the bolt when exposed to high heat and corrosive conditions.

3. FUEL INJECTOR PULLER

Fuel injectors, particularly those within the 6.7L Power Stroke are prone to become stuck inside the engine head. They're held down with a u-shaped clamp which is bolted to the head. After thousands of miles and high-heat exposure, the rubber O-ring on the fuel injector can become corroded and fuse the injector to the head.

Many Ford technicians have tried an after-market tool that also bolts to the head, like the injector clamp, then using a cast metal fork to ratchet the fuel injector out of the engine. Though this tool has worked, it does require a bit of set-up time and can warp over a few uses, causing it to walk off the injector while pulling it out of the engine.

We recommend the PowerPull Lift Kit. This tool does not need to be bolted to the head and can pull an injector in under a minute. Also, being made from machined steel, it will last far longer than the previously mentioned tool. If that doesn't do it, the lifetime warranty it is covered by should.

Technicians are under the gun to get trucks out of the service bay and back on the road. With a limited number of technicians coming into the field, the people in this profession are looking for more ways to become more productive. ProMAXX Tool's main objective is to provide these technicians with tools that make them more productive and confident professionals that can tackle any job that comes their way.

Power Stroke Kits From ProMAXX Tool

HAVE ADDITIONAL QUESTIONS ABOUT FORD DIESEL 6.7L POWER STROKE TOOLS?

GIVE PROMAXX TOOL A CALL, WE LOVE TO HEAR FROM OUR CUSTOMERS!

CALL 724-941-0941

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.